When designing a custom plastic first aid box, it is essential to consider fundamental requirements such as secure storage, easy accessibility, and organization.

A first aid kit prepares people for emergencies. In addition to including appropriate fills to respond to various injuries, using a suitable and well-designed container to keep supplies secure, organized, and easy to access is also critical in designing a first aid kit. With a variety of container options available, the choice depends on the specific scenario, for example, whether it’s indoor or outdoor or needs to be carried around or fixed in a particular place.

In this post, we will focus on first aid kit containers in plastic and explore the two most common methods used in bulk manufacturing: blow molding and injection molding.

Key Takeaways

- Injection molding is the most common method for manufacturing plastic first aid boxes. Blow molding is suitable for creating clamshell first aid boxes and wall stations.

- Both injection molding and blow molding require molds, but injection molding molds are generally more expensive.

- When designing a custom plastic first aid box, it is essential to consider fundamental requirements such as secure storage, easy accessibility, and organization.

Injection Molding

Introduction to Injection Molding

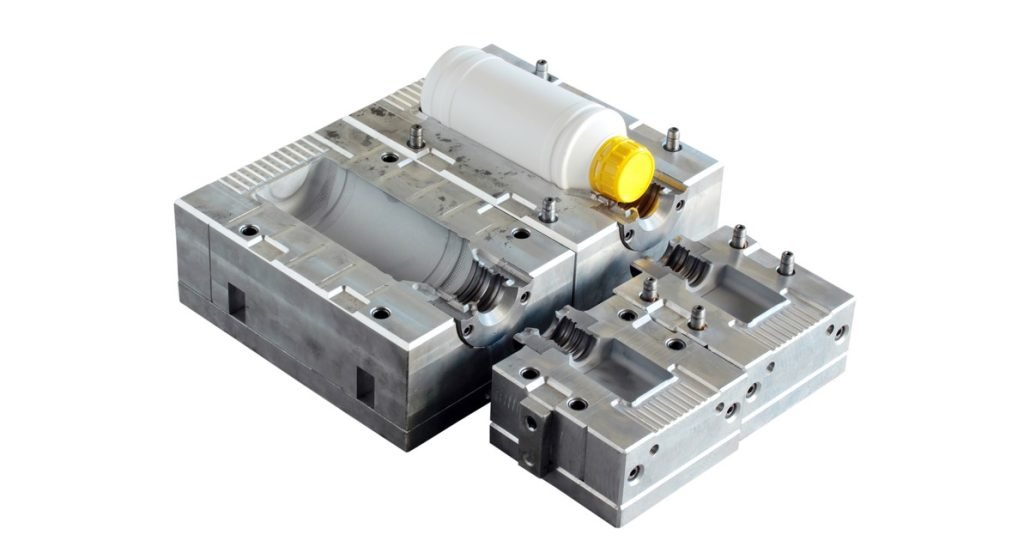

Most of the plastic first aid boxes available in the market are manufactured using injection molding. In the process, plastic resin is melted and injected into a mold cavity under high pressure. Then, the plastic is solidified in the cooling process, and the product is formed.

Mold or tooling is a critical component in injection molding. The mold design is crucial as it affects the quality and functionality of the plastic products. Moreover, the mold cost is a significant factor to consider as it significantly contributes to the overall manufacturing cost.

Some plastic first aid boxes contain multiple parts, such as the box body, the opening/closing device, the handle, and the bracket. Consequently, multiple molds are required for each part. Once the injection molding process produces these parts, they are assembled into the box.

Injection Mold Cost for First Aid Kit Container

Typically, the cost of the molds required for a first aid box varies between US$ 3,000 to US$ 20,000, depending on the size, complexity, cavity numbers in a mold, and other factors. Despite the high mold cost, the unit cost for each plastic box is relatively affordable, mainly because of the low material cost and the increased production efficiency of the molding process.

Blow Molding

Introduction to Blow Molding

Blow molding is a widely used manufacturing process in producing hollow and thin plastic parts. This technique is commonly employed in making products such as water bottles and thin-wall clamshell containers. In the first aid industry, blow molding is frequently used to create transparent clamshell first aid kit boxes and surface-mounted custom-fit storage units. Unlike injection molding, products made through blow molding tend to be thinner, although this is not always the case.

The blow molding process begins with melting plastic resin, which is then extruded into a tube known as a parison. The parison is then placed in a mold cavity, and the air is blown into it to shape it into the mold.

Blow Mold Cost for First Aid Kit Container

As with injection molding, the mold used in the blow molding process is critical to the quality and functionality of the final product. However, the cost of producing a blow mold is generally much lower than that of an injection mold, typically ranging from US$200 to US$2,000.

Comparison of two molding methods

Application

Blow molding and injection molding are two commonly used processes in plastic manufacturing. Blow molding is an efficient and economical method that produces lightweight and robust plastic containers, such as clamshell first aid boxes and wall stations. Injection molding, on the other hand, is a process suited for creating intricate designs and complex shapes.

Mold

Both processes require molds, but injection molding molds are generally more expensive due to their complexity. However, injection molding offers higher precision and tighter tolerances than blow molding, making it more suitable for products that require high accuracy and uniformity in their dimensions.

Find Out Which Molding Method Works for You & Get a Quote Today!

When to consider a custom private mold?

Pre-Made Plastic First Aid Containers

Acquiring pre-made plastic containers from the market can be a practical option for those who seek to avoid investing in a mold. This approach is particularly convenient for those who require small quantities of containers. However, it’s important to note that the design cannot be changed once a mold is created. Hence, customization with an existing design can be complex, even when it comes to modifying the thickness of the box.

On the other hand, when the available off-the-shelf product designs do not meet one’s specific requirements or when a large quantity of containers is needed, it’s recommended to consider designing and creating a custom mold. This allows for greater flexibility and the ability to tailor the container to unique needs. However, creating a custom mold requires a significant upfront investment in time and money.

Factors to consider in designing a first aid plastic box

Requirements

When designing an empty first aid box, it’s crucial to consider the fundamental requirements of a first aid kit.

- Secure storage of first aid supplies

- Easy accessibility and identification

- Organization and quick access to items

Considering these factors, the first aid container must have a well-designed door that is easy to open and close. The box needs to be sturdy to keep the supplies stored securely. Moreover, the container should have compartments that can hold supplies in an organized way. Finally, vivid colors or prominent labels should quickly identify the box. Additional features may be required for specialized first aid containers, such as those used for fishing or boating. For example, waterproofing is essential in such cases. While regular plastic kits are dust-proof in most cases, achieving high waterproofing ratings requires thorough considerations to ensure a tight seal.

Common Defects in the Plastic Containers

To gain insights into plastic first aid kit box design, we analyzed over 1,000 critical reviews on the products sold on Amazon. We have identified common defects that users have experienced with plastic containers. These reviews shed light on practical issues that are likely to occur. Based on our findings, here is a summary of defects and the possible causes.

- Damage during transit: The plastic cases are broken due to inadequate packaging or design flaws.

- Difficulty in opening and closing the case: The issue may be caused by poor design in the door opening mechanism or failure of mold inspection and validation before batch production.

- Inserts within the case that move around, causing disorganization: Design flaws or lack of proper mold inspection and validation before batch production.

- Flimsy box body or inserts that are damaged or distorted: Design issue that fails to consider the proper thickness for a sturdy box.

- Items falling off wall-mounted boxes: Design issues or missing inspection step of the mold before batch production.

We conclude that many complaints can be avoided through good design practices. It is important to thoroughly consider and evaluate the design of the first aid plastic box before proceeding with mold production.

How we can help with custom plastic container production

At Dawn Breeze, we have partnered with local manufacturing facilities on blow molding and injection molding to provide our clients with reliable plastic first aid containers. Check out more for our custom manufacturing service of plastic containers.